Ụkpụrụ ịgbado ọkụ laser: Igwe ịgbado ọkụ laserna-eji eriri laser dị elu na-egbuke egbuke n'elu igwe, na-ekpo ọkụ na mpaghara ahụ na obere ebe, na-agbazekwa ihe ahụ iji mepụta ọdọ mmiri a wụrụ awụ iji nweta nzube nke ịgbado ọkụ.

Akụkụ nke igwe ịgbado ọkụ laser:

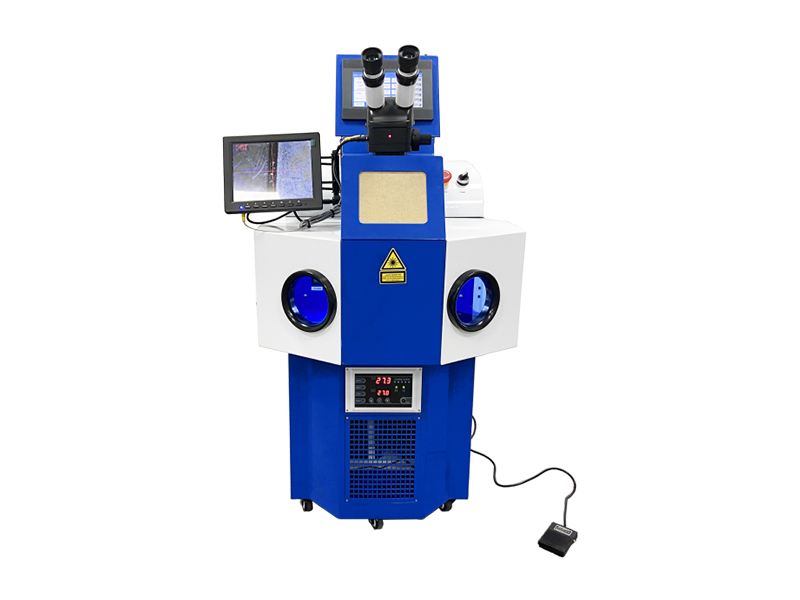

Ọ bụ ụdị ọhụrụ nke ịgbado ọkụ usoro, tumadi maka ịgbado ọkụ nke ezi akụkụ, nke nwere ike mezue ntụpọ ịgbado ọkụ, butt ịgbado ọkụ, stitch ịgbado ọkụ, akara ịgbado ọkụ, wdg, na elu akụkụ ruru, obere weld obosara, obere okpomọkụ emetụta mpaghara, obere okpomọkụ emetụtara mpaghara, obere okpomọkụ. deformation, na ịgbado ọkụ ọsọ.Ngwa ngwa ịgbado ọkụ, ewepụghị na mara mma nke ịgbado ọkụ, ọ dịghị mkpa ọgwụgwọ ma ọ bụ naanị mfe ọgwụgwọ mgbe ịgbado ọkụ, elu ịgbado ọkụ onuete, enweghị porosity, ziri ezi akara, obere mkpokọta ebe, elu n'ọnọdu ziri ezi, mfe mezue akpaaka.Ọ na-eji ọkụ ọkụ laser dị elu na-ekpo ọkụ na-ekpo ọkụ na obere mpaghara.The ike nke laser radieshon na-agbasa n'ime ihe site okpomọkụ conduction, agbaze ihe na-etolite a kpọmkwem a wụrụ awụ ọdọ mmiri, na mgbe dissolves abụọ ihe na kọntaktị ọnụ.

Ụdị igwe ịgbado ọkụ laser:

Kewara ụzọ abụọ—①Igwe ịgbado ọkụ laser ọlaA na-eji ya arụkwa oghere, ntụpọ ịgbado ọkụ, na ịrụzi ịgbado ọkụ ọla edo na ọla ọcha.

Nhọrọ nke ọla laser ịgbado ọkụ:

1)Igwe eji agbado ọkụ Laser ọla-iche mmiri Chiller

Laser ịgbado ọkụ reconfigures molekụla Ọdịdị nke yiri ma ọ bụ dissimitter ọla na weld, na-eme abụọ nkịtị alloys otu.Iji sistemụ nlele microscope pụrụ iche ma ọ bụ sistemụ nlele CCD na ngwa nzacha eletrọnịkị dị elu nwere ike chebe onye na-arụ ọrụ nke ọma, mmetụta ịgbado ọkụ kwụsiri ike ma bụrụ nke a pụrụ ịdabere na ya, na ọdịda ọdịda dị ala.

2) ỌLAIgwe ịgbado ọkụ laser-Erụnye mmiri oyi

Maka imeju porosity, re-tipping platinum ma ọ bụ ntọala tine ọla edo, ịrụzi ntọala bezel, rụkwaa / mezie mgbanaka na ọla aka na-ewepụghị okwute na mezie ntụpọ nrụpụta.Usoro nleba anya bụ usoro nlele microscope ma ọ bụ CCD nlekota na nleba anya.

3)Igwe eji agbado ọkụ Laser ọla-Model Desktọpụ

Ọ bụ ngwaahịa pụrụ iche maka ịgbado ọkụ laser ọla, nke a na-ejikarị maka oghere na ntụpọ ịgbado ọkụ na ọla edo na ọla ọla ọcha.Igwe ịgbado ọkụ laser bụ otu n'ime akụkụ dị mkpa nke ngwa teknụzụ nhazi ihe laser.A na-eji ya na-edobe ngwa ngwa nke ntụpọ uhie, ihe ngosi CCD nke usoro ihe nleba anya, na microscope nhọrọ.

A na-eji ya eme ihe maka nrụzi ịgbado ọkụ laser nke nnukwu na obere ebu.A na-eji pulses laser nwere ike dị elu na-ekpo ọkụ na mpaghara mpaghara na obere mpaghara.Ike nke radieshon laser na-agbasa n'ime ime ihe site na ikpo ọkụ, na ihe abụọ ahụ gbazere ma jikọta ọnụ.

Nhọrọ nke igwe ịgbado ọkụ laser ebu:

1)Igwe eji agbado ọkụ laser-Ụdị ejiri aka

Ọ na-anabata ọgbọ ọhụrụ nke fiber lasers ma kwadebere ya na isi ịgbado ọkụ laser dị elu, na-agbanwe agbanwe maka ihe nhazi dị iche iche.Ọrụ dị mfe, eriri weld mara mma, ọsọ ịgbado ọkụ ngwa ngwa na enweghị ihe ọ bụla.

2)3-AxisIgwe ịgbado ọkụ laser- Akpaaka Ụdị

Ọ nwere ike mezue akpaka ntụpọ ịgbado ọkụ, ma ịgbado ọkụ tojupụtara ịgbado ọkụ na akara ịgbado ọkụ site onwem na atọ axes ma ọ bụ anọ akụkụ bọl ịghasa table na ibubata servo akara usoro, aiming na mgbagwoju ụgbọ elu ogologo ahịrị.

3)Igwe na-agbado ọkụ na-ebu Laser-Ụdị akwụkwọ ntuziaka

tumadi maka ịgbado ọkụ nke mkpa-walled ihe na nkenke akụkụ.Ọ nwere ike ịghọta ntụpọ ịgbado ọkụ, butt ịgbado ọkụ, stitch ịgbado ọkụ, akara ịgbado ọkụ, wdg, na elu akụkụ ruru, obere weld obosara, obere okpomọkụ-emetụta mpaghara na obere deformation.

4)Igwe ịgbado ọkụ nke Cantilever Laser-Na Ume Ogwe aka

Site na ogwe aka cantilever, dabara adaba maka ịgbado ọkụ buru ibu.Enwere ike ịtụgharị ya na akụkụ na akụkụ niile, X, Y, Z axis na-ebugharị kpamkpam, dozie ịgbado ọkụ siri ike, welie arụmọrụ ọrụ.

Ihe dị n'elu bụ okwu mmeghe nke igwe ịgbado ọkụ laser.Ọ bụrụ na ịchọrọ ịmatakwu, ị nwere ike ịmụta site na njikọ dị na ngwaahịa ọ bụla.

Oge nzipu: Mee-05-2023